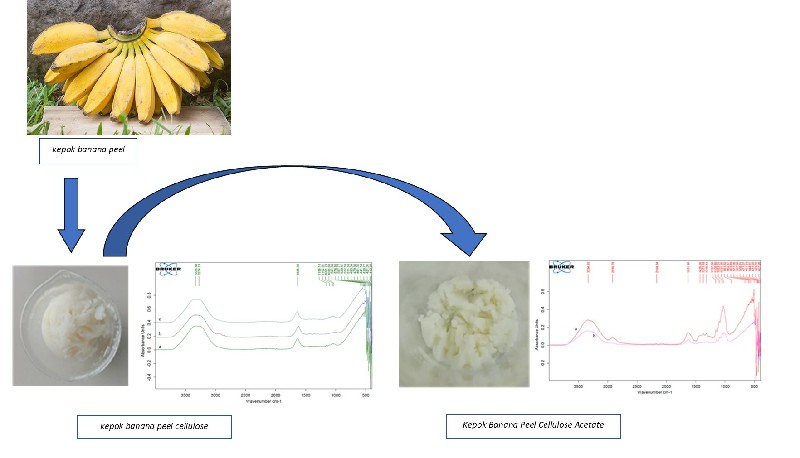

The Effect of NaOH Concentration and Acetylation Time on Synthesis of Kepok Banana Peel Cellulose Acetate

Downloads

The high production of kepok banana is generating a significant amount of peel waste, contributing to environmental pollution. To address this issue, an innovative solution is the conversion of kepok banana peel into cellulose acetate as raw material for membrane production. Therefore, this research aimed to manufacture kepok banana peel cellulose acetate using varying concentrations of 1%, 1.5%, and 2% NaOH solvent, with acetylation times of 2 hours and 2.5 hours, respectively. The optimal results were achieved using 1% NaOH with kepok banana peel cellulose content of 56.07%. Furthermore, the best acetylation time occurred at a duration of 2.5 hours, producing a cellulose acetate content of 38.23% and a 2.3% degree of substitution (DS). These results suggested that the optimal combination for producing membrane from kepok banana peel is 1% concentration with an acetylation time of 2.5 hours, classifying it as cellulose diacetate.

Downloads

[1] BPS. (2022). Produksi Pisang Di Indonesia dari Tahun 2013-2017.

[2]Mirwan, A., Indriyani, V., & Novianty, Y. (2018). Pembuatan Membran Ultrafiltrasi Dari Polimer Selulosa Asetat Dengan Metode Inversi Fasa. Konversi, 6(1), 11. DOI: 10.31213/k.v6i1.14

[3]Alvianto, D., Nurhadi, F. A. A., Putranto, A. W., Argo, B. D., Hermanto, M. B., & Wibisono, Y. (2022). Sintesis dan Karakterisasi Membran Selulosa Asetat dengan Penambahan Antibiofouling Alami Ekstrak Bawang Putih. ALCHEMY Jurnal Penelitian Kimia, 18(2), 193. DOI: 10.20961/alchemy.18.2.57199.193-204

[4]Novianti, P., & Setyowati, W. A. E. (2016). Pemanfaatan Limbah Kulit Pisang Kepok Sebagai Bahan Baku Pembuatan Kertas Alami Dengan Metode Pemisahan Alkalisasi. Prosiding Seminar Nasional Pendidikan Sains, 459-466.

[5]Zhaafirah, H., & Fitriyano, G. (2017). Pengaruh Kecepatan Pengadukan Terhadap Rendemen dan Identifikasi Selulosa Asetat Hasil Asetilasi dari Limbah Kulit Pisang Kepok. Jurnal Universitas Muhammadiyah Jakarta, 008(November), 1-8.

[6]Seto, A. S., & Sari, A. M. (2013). Pembuatan Selulosa Asetat Berbahan Dasar Nata De Soya. Konversi, 2, 1-12.

[7]Syamsu, K., & Kuryani, T. (2014). Cellulose acetate biofilm production from microbial cellulose nata de cassava. E-Jurnal Agroindustri Indonesia, 3(1), 126-133.

[8]Nurhayati, N., & Kusumawati, R. (2014). Sintesis Selulosa Asetat dari Limbah Pengolahan Agar. Jurnal Pascapanen dan Bioteknologi Kelautan dan Perikanan, 9(2), 97. DOI: 10.15578/jpbkp.v9i2.103

[9]Asparingga, H., Syahbanu, I., & Alimuddin, A. H. (2018). Pengaruh Volume Anhidrida Asetat Pada Sintesis Selulosa Asetat dari Sabut Kelapa (Cocos nucifera L.). Jurnal Kimia Khatulistiwa, 7(3), 10-17.

[10] Gaol, M., Sitorus, R., Yanthi, S., Surya, I., & Manurung, R. (2013). Pembuatan Selulosa Asetat Dari Α -Selulosa Tandan Kosong Kelapa Sawit. Jurnal Teknik Kimia USU, 2(3), 33-39. DOI: 10.32734/jtk.v2i3.1447

[11]Lismeri, L., Zari, P. M., Novarani, T., & Darni, Y. (2016). Sintesis Selulosa Asetat dari Limbah Batang Ubi Kayu. Jurnal Rekayasa Kimia dan Lingkungan, 11(2), 82-91.

Copyright (c) 2023 CHEESA: Chemical Engineering Research Articles

This work is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License.

With the receipt of the article by CHEESA Editorial Board and the decision to be published, the copyright regarding the article will be transferred to CHEESA Journal.

CHEESA has the right to multiply and distribute the article and every author is not allowed to publish the same article that was published in this journal.

This work is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License.

Under the following terms:

Attribution ” You must give appropriate credit, provide a link to the license, and indicate if changes were made. You may do so in any reasonable manner, but not in any way that suggests the licensor endorses you or your use.

NonCommercial ” You may not use the material for commercial purposes.

ShareAlike ” If you remix, transform, or build upon the material, you must distribute your contributions under the same license as the original.