Modeling and Simulation of Biomass Gasification with Aspen Plus for Different Types of Local Biomass from Riau Province

Downloads

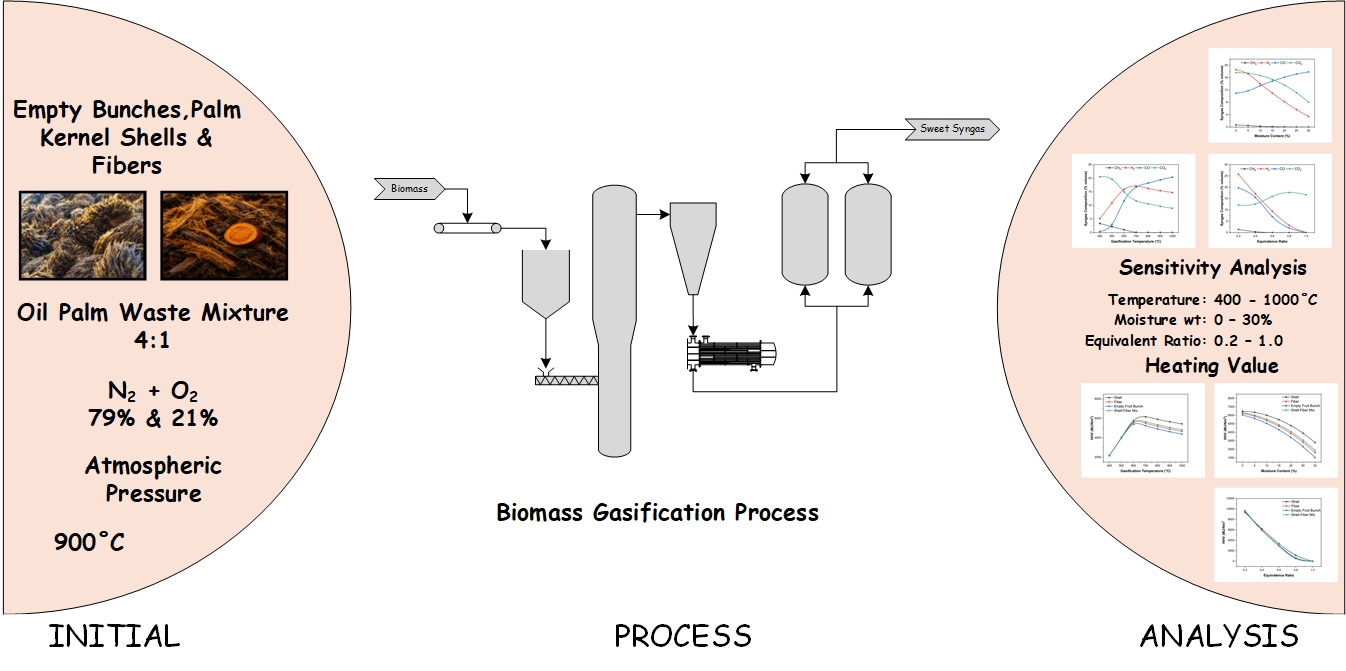

Gasification is a promising technology for electrical energy generation systems in palm oil mills. The syngas components, namely CH4, H2, and CO, produced from gasification can be used as fuel to produce steam, which will be applied in turbine generators to produce electricity. Therefore, this study aimed to simulate and validate a flowsheet model of gasification process for oil palm mill waste using Aspen Plus to achieve an optimal syngas composition, and conduct sensitivity analysis by varying gasification temperature, equivalent ratio, as well as correlating biomass moisture content to syngas composition. Biomass moisture content, equivalent ratio, and gasification temperature are important parameters that affect the chemical composition and heating value of syngas analyzed using the sensitivity analysis method. The results showed that the syngas composition was sensitive to the parameters of temperature, moisture content, and equivalent ratio. The operating conditions of gasification process to obtain a high heating value of syngas include 650˚C gasification temperature, 0% moisture content, and 0.2 equivalent ratios.

Downloads

Badan Pusat Statistik. (2023). Statisitk Kelapa Sawit Indonesia (Indonesia Oil Palm Statistics) 2022 (Vol. 16). Jakarta: Badan Pusat Statistik.

Paul, O. U., Akhator, P., John, I. H., Ndubuisi, I., Peter, A., & Godspower, O. (2015). Calorific Value of Palm Oil Residues for Energy Utilization. Ijeir, 4(4), 664–667. Retrieved from https://www.researchgate.net/publication/303685597

Siswanto, J. E. (2020). Analisis Limbah Kelapa Sawit Sebagai Bahan Bakar Boiler dengan Menggunakan Variasi Campuran Antara Fiber dan Cangkang Buah Sawit. Journal of Electrical Power Control and Automation (JEPCA), 3(1), 22–27. doi: 10.33087/jepca.v3i1.35

Meng, F., Meng, J., Zhang, D. (2018). Influence of higher equivalent ratio on the biomass oxygen gasification in a pilot scale fixed bed gasifier. J. Renewable Sustainable Energy, 10(5), 053101.

Mufid, F., & Anis, S. (2019). Pengaruh Jenis dan Ukuran Biomassa terhadap Proses Gasifikasi Menggunakan Downdraft Gasifier. Rekayasa Mesin, 10(3), 217–226.

Sivalaban, K., Hassan, S., Ya, H., & Pasupuleti, J. (2021). A review on the characteristic of biomass and classification of bioenergy through direct combustion and gasification as an alternative power supply. Journal of Physics: Conference Series, 1831, 28-29 December 2019

Mohammed, M. A. A., Salmiaton, A., Azlina, W. A. K. G. W., & Amran, M. S. M. (2012). Gasification of oil palm empty fruit bunches: A characterization and kinetic study. Bioresource Technology, 110, 628-636, doi: 10.1016/j.biortech.2012.01.056

Aktawan, A., Maryudi, Siti, S., & Erna, A. (2020). Gasification of Oil Palm Shells and Empty Fruit Bunches to Produce Gas Fuel. Key Engineering Materials, 849, 3-7, doi:.4028/www.scientific.net/KEM.849.3

Paiva, M., Vieira, A., Gomes, H. T., & Brito, P. (2021). Simulation of a Downdraft Gasifier for Production of Syngasfrom Different Biomass Feedstocks. ChemEngineering, 5(2). doi: 10.3390/chemengineering5020020

Samiran, N. A., Jaafar, M. N. M., Ng, J., Lam, S. S., & Chong, C. T. (2016). Progress in biomass gasification technique - With focus on malaysian palm biomass for syngas production. Renewable and sustainable Energy Reviews, 62, 1047 - 1062, doi: 10.1016/j.rser.2016.04.049

Surahmanto, F., Saptoadi, H., Sulistyo, H., & Rohmat, T. A. (2020). Investigation of the pyrolysis characteristics and kinetics of oil-palm solid waste by using coats–redfern method. Energy Exploration and Exploitation, 38(1), 298–309. doi: 10.1177/0144598719877759

González-Vázquez, M. P., Rubiera, F., Pevida, C., Pio, D. T., & Tarelho, L. A. C. (2021). Thermodynamic analysis of biomass gasification using aspen plus: Comparison of stoichiometric and non-stoichiometric model. Energies, 14(1). doi: 10.3390/en14010189

Singh, D. K., & Tirkey, J. V. (2022). Process modelling and thermodynamic performance optimization of biomass air gasification fuelled with waste poultry litter pellet by integrating Aspen plus with RSM. Biomass and Bioenergy, 158. doi: 10.1016/j.biombioe.2022.106370

Striugas, N., Zakarauskas, K., Džiugys, A., Navakas, R., & Paulauskas, R. (2014). An evaluation of performance of automatically operated multi-fuel downdraft gasifier for energy production. Applied Thermal Engineering, 73(1), 1151–1159. doi: 10.1016/j.applthermaleng.2014.09.007

Primandanu, G. S., & Putra, A. B. K. (2022). Studi Simulasi dan Eksperimental Pengaruh Equivalent Ratio dan Temperatur Udara Inlet pada Proses Gasifikasi Tongkol Jagung Terhadap Gasifier Tipe Downdraft Berdasarkan Prinsip Energi dan Eksergi. Jurnal Teknik ITS, 11(1), 1–8. doi: 10.12962/j23373539.v11i1.82095

Bertling, M., & Milstig, A. (2022). Electrified Reforming of Biogas to Hydrogen for Industrial Furnaces with Negative Carbon Emissions : A Feasibility Study Sammanfattning. KTH Royal Institute of Technology.

Puig-Arnavat, M., Bruno, J. C., & Coronas, A. (2012). Modified thermodynamic equilibrium model for biomass gasification: A study of the influence of operating conditions. Energy and Fuels, 26(2), 1385–1394. doi: 10.1021/ef2019462

Tavares, R., Monteiro, E., Tabet, F., & Rouboa, A. (2020). Numerical investigation of optimum operating conditions for syngas and hydrogen production from biomass gasification using Aspen Plus. Renewable Energy, 146, 1309–1314. doi: 10.1016/j.renene.2019.07.051

Sidek, F. N., Abdul Samad, N. A. F., & Saleh, S. (2020). Review on effects of gasifying agents, temperature and equivalent ratio in biomass gasification process. IOP Conference Series: Materials Science and Engineering, 863(1), 1–9. doi: 10.1088/1757-899X/863/1/012028

Kumar, M., Paul, B., & Yadav, D. S. (2016). Effect of moisture content and equivalent ratio on the gasification process for different biomass fuel. International Journal of Mechanical Engineering and Technology, 7(6), 209–220.

Copyright (c) 2025 CHEESA: Chemical Engineering Research Articles

This work is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License.

With the receipt of the article by CHEESA Editorial Board and the decision to be published, the copyright regarding the article will be transferred to CHEESA Journal.

CHEESA has the right to multiply and distribute the article and every author is not allowed to publish the same article that was published in this journal.

This work is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License.

Under the following terms:

Attribution ” You must give appropriate credit, provide a link to the license, and indicate if changes were made. You may do so in any reasonable manner, but not in any way that suggests the licensor endorses you or your use.

NonCommercial ” You may not use the material for commercial purposes.

ShareAlike ” If you remix, transform, or build upon the material, you must distribute your contributions under the same license as the original.