Enhancement of the Quality of Onion Drying Using Tray Dryer

Downloads

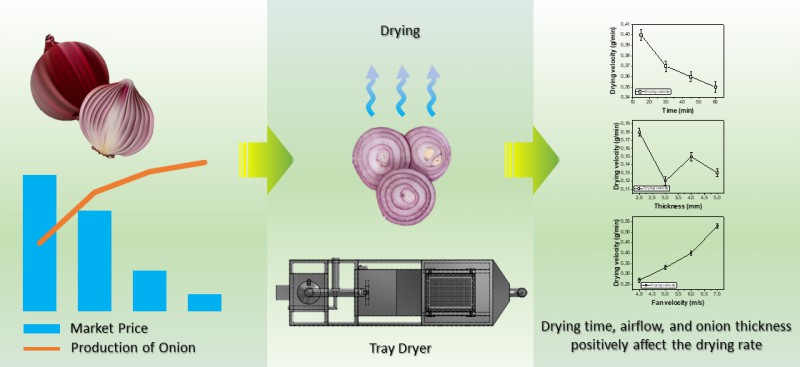

Previous reports showed that there has been a continuous increase in the annual production of onion in Indonesia, and it is inversely proportional to the market price. The price drop is often caused by the high water content, which makes it easy to rot. Preservation of onions through a tray dryer is a good preservation method because it is effective and does not require much energy. Therefore, this study aims to determine the effect of variations in time, material thickness, and air velocity on the drying rate of onions. The samples were sliced to a size of 2 - 5 mm, followed by drying for 60 min using a tray dryer with different air rates between 4 - 7 m/s, and the rate of the process was observed every 15 min. The results showed that the drying time reduced the humidity in the chamber. The highest rate of 0.525 g/min was obtained at the peak air rate of 7 m/s. ANOVA results revealed that variations in time, onion thickness, and flow rate have a significant effect on increasing the drying rate of onions. This indicates that the method can be an effective and efficient solution to optimize the drying of the commodity.

Downloads

Adha, F., Mustaqimah, & Agustina, R. (2018). Study of Thin Layer Drying Turmeric (Curcuma domestica VAL.) Characteristics Using Tray Dryer. Jurnal Ilmiah Mahasiswa Pertanian, 3(1), 1-11.

Alimny, A. N., Muharja, M., & Widjaja, A. (2019). Kinetics of Reducing Sugar Formation from Coconut Husk by Subcritical Water Hydrolysis. Journal of Physics: Conference Series, 1373(1), 12006. DOI: 10.1088/1742-6596/1373/1/012006

Darianto, Amrinsyah, & Sitohang, H. T. S. (2019). Analisa Pengaruh Waktu dan Turbulensi Asap Pada Mesin Pengering Ikan Lele. Journal of Mechanical Engineering Manufactures Materials and Energy, 3(2), 130-142. DOI: 10.31289/jmemme.v3i2.3029

Dewayani, W., Samsuri, R., Septianti, E., & Halil, W. (2019). Kajian Jenis Pengeringan dan Beberapa Bahan Pengisi terhadap Kualitas Bubuk Bawang Merah Varietas Pikatan. Jurnal Pengkajian dan Pengembangan Teknologi Pertanian, 22(3), 251-262. DOI: 10.21082/jpptp.v22n3.2019.p251-262

Elfiana, E., Usman, U., Sami, M., Ridwan, R., Intan, S. K., Rahmawati, C. A., & Pardi, P. (2021). Desiminasi Oven Drying Vacuum ( ODV ) Untuk Pengeringan Rempah Bandrek Siap Saji Di Desa Kumbang Kecamatan Syamtalira Aron Kabupaten Aceh Utara. Proceeding Seminar Nasional Politeknik Negeri Lhokseumawe, 5(1), 147-154.

Effendy, S., Syarif, A., Wardani, D. K., & Amalia, I. (2019). Prototype Rotary Dryer Dengan Bahan Bakar Biomassa Prototype Rotary Dryer With Biomass Fuels Reviewed From the Influence of Air Flow Rate and. Jurnal Kinetika, 10(01), 1-6.

Fachri, B. A., Rizkiana, M. F., & Muharja, M. (2020). A Kinetic Study on Supercritical Carbon-dioxide Extraction of Indonesian A Kinetic Study on Supercritical Carbon-dioxide Extraction of Indonesian Trigona sp . Propolis. IOP Conf. Series: Materials Science and Engineering, 742(012001), 1-5. DOI: 10.1088/1757-899X/742/1/012001

Hasibuan, R., Pane, Y. M., & Hanief, S. (2020). Effect of Air Velocity and Thickness to Drying Rate and Quality Temulawak (Curcum Xanthorrhiza Roxb) using Combination Solar Moleculer Sieve Dryer, Proceedings of the International Conference of Science, Technology, Engineering, Environmental and Ramification Researches, 389-394. DOI: 10.5220/0010103503890394

Manfaati, R., Baskoro, H., & Rifai, M. M. (2019). Pengaruh Waktu dan Suhu terhadap Proses Pengeringan Bawang Merah menggunakan Tray Dryer. Fluida, 12(2), 43-49. DOI: 10.35313/fluida.v12i2.1596

Manfaati, R., Baskoro, H., & Rifai, M. M. (2020). Characterization of Drying Shallots (Allium cepa L.) Using Tray Dryer. CHEESA: Chemical Engineering Research Articles, 3(2), 71-78. DOI: 10.25273/cheesa.v3i2.7660.71-78

Muharja, M., Albana, I., Zuhdan, J., Bachtiar, A., & Widjaja, A. (2019). Reducing Sugar Production in Subcritical Water and Enzymatic Hydrolysis using Plackett- Burman Design and Response Surface Methodology. Jurnal Teknik ITS, 8(2), 56-61. DOI: 10.12962/j23373539.v8i2.49727

Muharja, M., Fadhilah, N., Darmayanti, R. F., Sangian, H. F., Nurtono, T., & Widjaja, A. (2020). Effect of severity factor on the subcritical water and enzymatic hydrolysis of coconut husk for reducing sugar production. Bulletin of Chemical Reaction Engineering & Catalysis, 15(3), 786-797. DOI: 10.9767/BCREC.15.3.8870.786-797

Muharja, M., Umam, D. K., Pertiwi, D., Zuhdan, J., Nurtono, T., & Widjaja, A. (2019). Enhancement of sugar production from coconut husk based on the impact of the combination of surfactant-assisted subcritical water and enzymatic hydrolysis. Bioresource Technology, 274(November 2018), 89-96. DOI: 10.1016/j.biortech.2018.11.074

Prasetyaningsih, Y., & Mulyanti, S. (2018). Pengaruh Suhu dan Laju Alir Pengeringan pada Bawang Putih Menggunakan Tray Dryer. Prosiding Seminar Nasional Teknik Kimia "Kejuangan" Pengembanagn Teknologi Kimia untuk Pengolahan Sumber Daya Alam Indonesia, (April), 1-6.

Purnamasari, I., Meidinariasty, A., & Hadi, R. N. (2019). Prototype Alat Pengering Tray Dryer Ditinjau dari Pengaruh Temperatur dan Waktu Terhadap Proses. Jurnal Kinetika, 10(03), 25-28.

Rahayuningtyas, A., & Kuala, S. I. (2016). Pengaruh Suhu dan Kelembaban Udara pada Proses Pengeringan Singkong (Studi Kasus: Pengering Tipe Rak). Jurnal Penelitian dan Pengabdian Masyarakat, 4(1), 99-104.

Ridhatullah, M. A., & Hasibuan, R. (2019). Effect of Material Thickness and Amount of Desiccant on Drying Rate of Ginger (Zingiber officinale Roscoe) at Solar Dryer Integrated with Desiccant. Jurnal Teknik Kimia, 08(2), 61-66. DOI: 10.32734/jtk.v8i2.1882

Sari, D. K., & Prabawa, S. (2019). Effect of drying time and temperature on the characteristics of fig leaf tea (Ficus carica l.). Jurnal Teknologi Hasil Pertanian, 12(2), 68-77.

Sari, D. K., Kustiningsih, I., & Lestari, R. S. D. (2017). Pengaruh Suhu dan Waktu Pengeringan terhadap Mutu Rumput Laut Kering. Jurnal Teknika, 13(1), 43-50.

Sari, D. K., & Lestari, R. S. D. (2016). Pengaruh Laju Alir Udara Pengering terhadap Pengeringan Kulit Manggis. Teknika: Jurnal Sains dan Teknologi, 12(1), 35. DOI: 10.36055/tjst.v12i1.6614

Statistika, B. P. (2021). Provinsi Jawa Barat Dalam Angka 2021.

Ummah, N., Purwanto, Y. A., & Suryani, A. (2018). Penentuan Konstanta Laju Pengeringan Bawang Merah (Allium ascalonicum L.) Iris Menggunakan Tunnel Dehydrator. Warta IHP: Journal of Agro-based Industry, 33(2), 49-56.

Yando, A. M., & Paramita, V. (2017). Studi Pengaruh Suhu Dan Ketebalan Irisan Terhadap Kadar Air , Laju Pengeringan Dan Karakteristik Fisik Ubi Kayu Dan Ubi Jalar. Metana, 13(1), 23-29. DOI: 10.14710/metana.v13i1.17514

Yanti, A. T. Y., Abizard, A., Fitriani, Al Fatih, M., & Anggara, M. (2021). Mesin Pengering Bawang Merah Menggunakan Double Blower dan Sensor Suhu DHT22 Arduino di Desa Brangkolong Kecamatan Plampang, Sumbawa. Jurnal Teknik dan Sains, 2(1), 1-7.

Zamharir, Sukmawaty, & Priyati, A. (2016). Analysis of Heat Energy Utilizationin Onion (Allium ascalonicum, L.) Drying using Green Houses Gasses (GHG) Dryer. Jurnal Ilmiah Rekayasa Pertanian dan Biosistem, 4(2), 264-274.

Copyright (c) 2022 CHEESA: Chemical Engineering Research Articles

This work is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License.

With the receipt of the article by CHEESA Editorial Board and the decision to be published, the copyright regarding the article will be transferred to CHEESA Journal.

CHEESA has the right to multiply and distribute the article and every author is not allowed to publish the same article that was published in this journal.

This work is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License.

Under the following terms:

Attribution ” You must give appropriate credit, provide a link to the license, and indicate if changes were made. You may do so in any reasonable manner, but not in any way that suggests the licensor endorses you or your use.

NonCommercial ” You may not use the material for commercial purposes.

ShareAlike ” If you remix, transform, or build upon the material, you must distribute your contributions under the same license as the original.