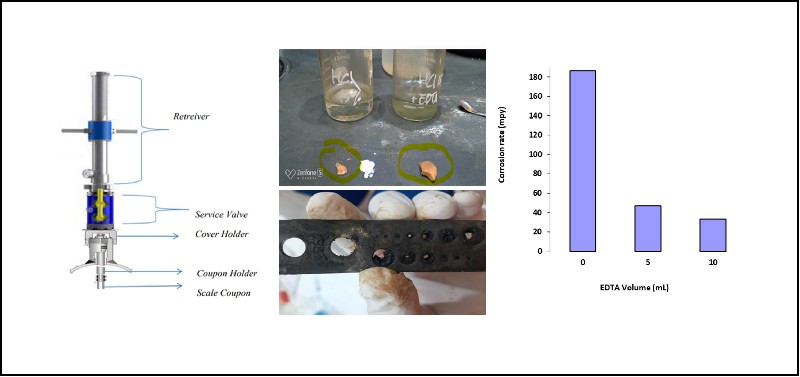

Effect of EDTA Addition on Acidizing Treatment Process

Downloads

Acidizing treatment is commonly used to solve scale problem on production equipment. In this process, Hydrochloric acid (HCl) is often used to treat CaCO3 scale, posing the risk of pipe corrosion due to its high corrosive characteristics. Thus, the purpose of this study was to determine the impact of adding EDTA additive into HCl solution during the acidifying treatment procedure. The methodology included various stages such as scale identification, chemical scale removal test using 7.5% and 15% HCL solution, 15% HCl solution test with EDTA as an additive, and corrosion determination using corrosion coupon. The results showed that 15% HCl solution was very effective in removing CaCO3 scale but had a high corrosion rate of 186.255 mpy. Furthermore, the addition of 10 mL EDTA solution as an additive removed scale and reduced corrosion rate by approximately 85%.

Downloads

[1] Irawan, A., & Isjudarto, A. (2016). Evaluasi Penanggulangan Problem Scale Pada Flowline Sumur Tlj-Xxx Di Pt. Pertamina Ep Asset Ii Field Prabumulih Sumatera Selatan. Teknik Pertambangan STTNAS Yogyakarta, 1-6.

[2] Silva, C., Filho, D., Zanin, M., & Panossian, Z. (2021). Impact of Crude Oil Emulsion on Pipeline Corrosion. Journal of Petrochemical Engineering, 1(1), 11-19. DOI: 10.36959/901/249

[3] Alighiri, D., Fatmala, C., Syafi, I., & Haditya, E. B. (2018). Studi Pembentukan Scale CaCO3 dan CaSO4 pada Air Formasi Sumur Minyak di Cepu, Indonesia. Fisika, 8(1), 28-36. DOI: 10.15294/jf.v8i1.14496

[4] Ibrahim, P. A., & Fajri, A. N. (2020). Analisa Laju Pertumbuhan Silica Scaling pada Pipa Air Kondensat Scrubber Unit 5 di Industri Geothermal. Molecules, 2(1), 1-12. DOI: 10.36418/jist.v1i4.42

[5] Musmuliadi. (2020). Scale Pada Pipa Produksi Area Minas Dengan Injeksi Chemical Scale Inhibitor, 7(1), 69-76. DOI: 10.37859/jst.v7i1.2352

[6] Fatra, F., & Suwignyo, J. (2020). Analisa Pengaruh Penambahan Asam Tartrat Terhadap Pembentukan Kerak Di Dalam Pipa Pengeboran Minyak Bumi. Journal of Automotive Technology Vocational Education, 1(2), 1-8. DOI: 10.31316/jatve.v1i2.991

[7] Septiani, M., Santoso, K., & Abdul Majid, R. (2019). Efektivitas Asam Nitrat (HNO3) Sebagai Pelarut Alternatif Pada Proses Acid Wash Terhadap Plate Electrolyzer Di Pt Kaltim Nitrate Indonesia. Journal of Chemical Process Engineering, 3(2), 17. DOI: 10.33536/jcpe.v3i2.258

[8] Kinasih, R. C., Amin, M., & Prabu, U. A. (2013). Analisa Hasil Acidizing Treatment untuk Menanggulangi Scale CaCO3 dalam Upaya Mengoptimalkan Kemampuan Berproduksi Sumur R-11 PT. Pertamina EP Asset 2 Limau Field. Journal of Earth Energy Engineering, 7(April), 1.

[9] Gamal, H., Elkatatny, S., Al-Afnan, S., & Bahgat, M. (2021). Development of a Unique Organic Acid Solution for Removing Composite Field Scales. ACS Omega, 6(2), 1205-1215. DOI: 10.1021/acsomega.0c04335

[10] Al-Shargabi, M., Davoodi, S., Wood, D. A., Ali, M., Rukavishnikov, V. S., & Minaev, K. M. (2022). A critical review of self-diverting acid treatments applied to carbonate oil and gas reservoirs. Petroleum Science. DOI: 10.1016/j.petsci.2022.10.005

[11] Tian, Y., Guo, W., Wang, W., Wang, B., Zhang, P., & Zhao, T. (2023). Influence of organic corrosion inhibitors on steel corrosion in concrete under the coupled action of freeze-thaw cycles and chloride attack. Construction and Building Materials, 368, 130385. DOI: 10.1016/j.conbuildmat.2023.130385

[12] Kahkesh, H., & Zargar, B. (2023). Estimating the anti-corrosive potency of 3-nitrophthalic acid as a novel and natural organic inhibitor on corrosion monitoring of mild steel in 1 M HCl solution. Inorganic Chemistry Communications, 158, 111533. DOI: 10.1016/j.inoche.2023.111533

[13] Kementerian Energi dan Sumber Daya Mineral. (2020). Sintesis Aditif Scale Removal Berbasis Asam Organik untuk Penanganan Scale Silika dan Karbonat Di Sumur Migas dan Panas Bumi. Jakarta.

[14] Kayadoe, V. (2018). Kinerja arginin sebagai inhibitor korosi baja SS-304 dalam larutan HCl. MjoCE, 8(2), 103-112. DOI: 10.30598/MJoCEvol8iss2pp103-112

[15] Bolzoni, F., Brenna, A., & Ormellese, M. (2022). Recent advances in the use of inhibitors to prevent chloride-induced corrosion in reinforced concrete. Cement and Concrete Research, 154, 106719. DOI: 10.1016/j.cemconres.2022.106719

[16] Chacon, O. G., & Pournik, M. (2022). Matrix Acidizing in Carbonate Formations. Processes. DOI: 10.3390/pr10010174

Copyright (c) 2023 CHEESA: Chemical Engineering Research Articles

This work is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License.

With the receipt of the article by CHEESA Editorial Board and the decision to be published, the copyright regarding the article will be transferred to CHEESA Journal.

CHEESA has the right to multiply and distribute the article and every author is not allowed to publish the same article that was published in this journal.

This work is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License.

Under the following terms:

Attribution ” You must give appropriate credit, provide a link to the license, and indicate if changes were made. You may do so in any reasonable manner, but not in any way that suggests the licensor endorses you or your use.

NonCommercial ” You may not use the material for commercial purposes.

ShareAlike ” If you remix, transform, or build upon the material, you must distribute your contributions under the same license as the original.