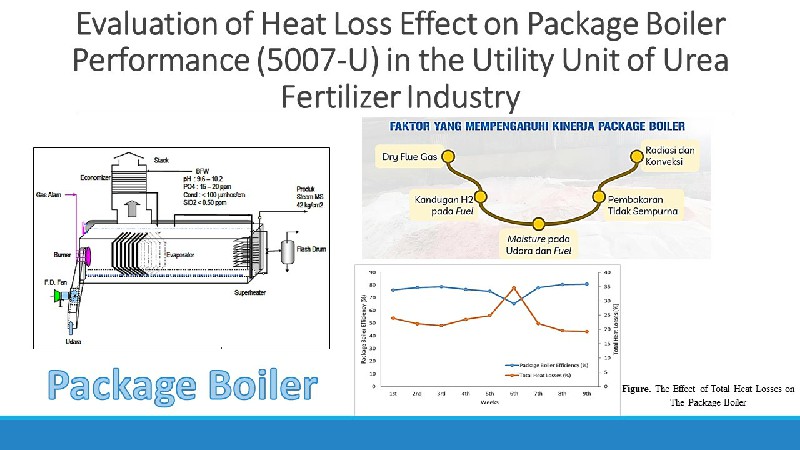

Determination of Content and Oil Losses in Meal through Palm Kernel Pressing Process at PT XYZ Belawan

Downloads

PT XYZ Belawan has a kernel crushing plant unit that produces Crude Palm Kernel Oil (CPKO) with 700 tons/day capacity. Palm kernel processing is carried out in two pressing stages. The first stage or first press produces oil and cake, while the second stage or second press produces oil and meal. The meal still contains 7-8% of the oil content. This study is aimed to determine the amount of CPKO yield, oil content, and oil losses in a meal during the pressing palm kernel process. The method used was the calculation of the mass balance in each process flow. The mass balance calculation is carried out after collecting the secondary data from the factory, including the analysis of water content, solids, FFA, and oil content. Based on the calculation results, CPKO yield was 48.10% of the average kernel mass rate of 714.7155 tons and met the plant standard of at least 44%. Furthermore, the average yield of oil content from the meal was 7.45% and oil losses were 3.86%.

Downloads

Alfian, A., Wardana, A., Yasmin, & Lya. (2016). Analisis Kehilangan Minyak Pada Crude Palm Oil Dengan Metode Statistical Process Control Pada PT Bastian Olah Sawit Tungkal Palembang. Jurnal Ilmiah Teknik Industri, 1(5), 36-40.

Asarta, C. J., & Schmidt, J. R. (2020). The effects of online and blended experience on outcomes in a blended learning environment. Internet and Higher Education, 44(June 2018), 100708. DOI: 10.1016/j.iheduc.2019.100708

Bello, E. I., Oguntuase, B., Osasona, A., & Mohammed, T. I. (2015). Characterization and engine testing of palm kernel oil biodiesel. European Journal of Engineering and Technology, 3(3), 1-14.

Daulay, H. B., Sudibyo, P. I., & Subha, M. H. (2019). Profile and Consistency of Kernel Quality Pt. Daria Dharma Pratama Lubuk Bento Palm Oil Processing Industry. Jurnal Agroindustri, 9(2), 109-116. DOI: 10.31186/j.agroindustri.9.2.109-116

Dewan Standardisasi Nasional. (1987). Crude palm kernel fatty acid (SNI 01-0024-1987). Indonesia. [Sources]

Dianto, F. (2017). Pengelolalaan Panen Kelapa Sawit Pelantaran Agro Estate. Bogor: IPB.

Ezeoha, S. L., Akubuo, C. O., & Ani, A. O. (2012). Indigenous Design and Manufacture of Palm Kernel Oil Screw Press in Nigeria: Problems and Prospects. International Journal of Applied Agricultural Research, 7(2), 67-82. [Sources]

Ezeoha, S. L., Akubuo, C. O., Odigboh, E. U., & Arallo, M. (2017). Performance evaluation of Magnus screw press (Model MS-100) for palm kernel oil extraction. Nigerian Journal of Technology, 36(2), 636. DOI: 10.4314/njt.v36i2.40

Hasballah, I. T., & Siahaan, E. W. B. (2018). Pengaruh Tekanan Screw Press Pada Proses Pengepresan Daging Buah Menjadi Crude Palm Oil. Darma Agung, XXVI, 722-729.

Jaeba, K. A., Lestari, E. T., & Adelino, M. I. (2021). Oil Losses Pada Fibre From Press Cake Di Pt. Amp Plantation Unit Pom. Jurnal Teknologi Dan Sistem Informasi Bisnis, 3(1), 234-239. DOI: 10.47233/jteksis.v3i1.220

Kasmin, H., Lazim, A. M., & Awang, R. (2016). Effect of Heat Treatments on the Yield, Quality and Storage Stability of Oil Extracted From Palm Fruits. Malaysian Journal of Analytical Science, 20(6), 1373-1381. DOI: 10.17576/mjas-2016-2006-16

Larasati, N., Chasanah, S., Machmudah, S., & Winardi, S. (2016). Studi Analisa Ekonomi Pabrik CPO (Crude Palm Oil) dan PKO (Palm Kernel Oil) Dari Buah Kelapa Sawit. Jurnal Teknik ITS, 5(2). DOI: 10.12962/j23373539.v5i2.16851

Louis, E. S., Akubuo, C. O., & Odigboh, E. U. (2020). Effect of some kernel factors on palm kernel oil extraction using a screw press. Agricultural Engineering International: CIGR Journal, 22(1), 156-161.

Majid, R. A., Mohammad, A. W., & May, C. Y. (2012). Properties of residual palm pressed fibre oil. Journal of Oil Palm Research, 24(APRIL), 1310-1317.

Purwanti, A., & Rahmawati. (2019). Analisis Proses Pemisah Kadar Produksi Crude Palm Oil (CPO) Di Ptp Nusantara 1 Tanjung Seumantoh-Aceh Tamiang. Jurnal Hadron, 1(1), 5-8.

PT. XYZ. (2019). Katalog PT. XYZ Belawan. Sumatera Utara.

Rahardja, I. B., & Ramadhan, A. I. (2020). Identification of Palm Oil Mill Throughput Capacity of 60 tons/hour (Case Study at XYZ Palm Oil Mill). Journal of Applied Science and Advanced Technology Journal Homepage, 83-86. [Sources]

Ramirez-Niño, M. Á., Jiménez-Forero, J. A., Bernal-Salazar, J. P., & Osorio-Dueñas, M. D. (2018). Characterization of oil extracted from the kernel of the fruit of cumare's palm (Astrocaryum chambira barret). Revista Facultad Nacional de Agronomia Medellin, 71(1), 8415-8422. DOI: 10.15446/rfna.v71n1.69589

Rantawi, A. B., Mahfud, A., & Situmorang, E. R. (2017). Korelasi Antara Kadar Air pada Kernel Terhadap Mutu Kadar Asam Lemak Bebas Produk Palm Kernel Oil Yang Dihasilkan ( Studi Kasus pada PT XYZ ). Industrial Engineering Journal, 6(1), 36-42.

Rinaldi, R., Pranoto, S., & Afriza, R. (2017). Studi Eksperimen Karakteristik Mekanik Material Screw Press Kapasitas 10-14 Ton/Jam di Lingkungan Pabrik Kelapa Sawit. Jurnal Surya Teknika, 5(01), 6-18. DOI: 10.37859/jst.v5i01.350

Simatupang, D. F., Saragih, G., & Simbolon, D. M. C. (2021). Studi Penentuan Perolehan dan Kehilangan Minyak dari Lumpur Buangan Proses pada Unit Decanter di Pabrik Kelapa Sawit PT. SPTG. In Seminar Nasional Teknologi Industri VII (pp. 376-382).

Simatupang, D. F., Tarigan, J., & Mansyur. (2020). The effect of active carbon adsorbents from some wastes in reducing free fatty acids and acid number to improve vco quality. IOP Conference Series: Materials Science and Engineering, 885(1), 6-11. DOI: 10.1088/1757-899X/885/1/012011

Simatupang, D. F., Yunianto, & Sihaloho, E. D. W. (2021). Analisa Kebutuhan Batu Bara pada Unit Dryer dalam Pengeringan Pupuk NPK di PT AGS Medan. CHEESA: Chemical Engineering Research Articles, 4(1), 11-17. DOI: 10.25273/cheesa.v4i1.7830.11-17

Sulaiman, & Randa, R. (2018). Pengaruh Temperatur Terhadap Efisiensi Sterilizer Dan Kualitas Minyak Yang Dihasilkan. Menara Ilmu, XII(10), 1-8.

Tarigan, J., & Simatupang, D. F. (2019). Uji Kualitas Minyak Goreng Bekas Pakai Dengan Penentuan Bilangan Asam, Bilangan Peroksida Dan Kadar Air. Ready Star , 2(1), 6-10.

Ulimaz, A., Hidayah, S. N., & Ningsih, Y. (2021). Analisis Oil Losses pada Proses Pengolahan Minyak Inti Kelapa Sawit di PT . XYZ dengan Metode Seven Tools Oil Losses Analysis of Palm Kernel Oil Processing Using Seven Tools Method. Jurnal Teknologi Agroindustri, 8(2), 124-134.

Wahyudi, J., Renjani, R. A., & Hermantoro. (2012). Analisis Oil Losses pada Fiber dan Broken Nut di Unit Screw Press dengan Variasi Tekanan. Prosiding Seminar Nasional PERTETA, (July), 399-404.

Yulianto. (2020). Analisis Quality Control Mutu Minyak Kelapa Sawit Di Pt. Perkebunan Lembah Bhakti Aceh Singkil. Amina, 1(2), 72-78. DOI: 10.22373/amina.v1i2.36

Yunos, N. S. H. M., Baharuddin, A. S., Md Yunos, K. F., Hafid, H. S., Busu, Z., Mokhtar, M. N., ... Som, A. M. (2015). The physicochemical characteristics of residual oil and fibers from oil palm empty fruit bunches. BioResources, 10(1), 14-29. DOI: 10.15376/biores.10.1.14-29

Zulkefli, F., Othman, N., Syahlan, S., Zaini, M. R., & Bakar, M. A. (2017). Fresh Fruit Bunch Quality and Oil Losses in Milling Processes As Factors That Affect the Extraction Rate of Palm Oil. International Journal of Agriculture, 5(June), 99-103.

Copyright (c) 2022 CHEESA: Chemical Engineering Research Articles

This work is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License.

With the receipt of the article by CHEESA Editorial Board and the decision to be published, the copyright regarding the article will be transferred to CHEESA Journal.

CHEESA has the right to multiply and distribute the article and every author is not allowed to publish the same article that was published in this journal.

This work is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License.

Under the following terms:

Attribution ” You must give appropriate credit, provide a link to the license, and indicate if changes were made. You may do so in any reasonable manner, but not in any way that suggests the licensor endorses you or your use.

NonCommercial ” You may not use the material for commercial purposes.

ShareAlike ” If you remix, transform, or build upon the material, you must distribute your contributions under the same license as the original.