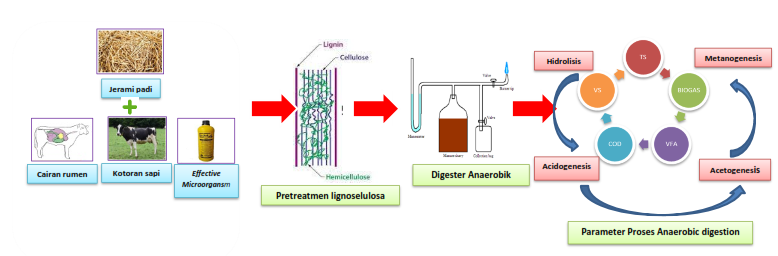

Produksi Biogas dari Jerami Padi Menggunakan Cairan Rumen dan Kotoran Sapi

Abstract

Keywords

Full Text:

DOWNLOAD PDFReferences

Alfa, I. M., Dahunsi, S. O., Iorhemen, O. T., Okafor, C. C., Ajayi, S. A. (2014). Comparative evaluation of biogas production from Poultry droppings, Cow dung and Lemon grass. Bioresource Technology. 157, 270–277, DOI: 10.1016/j.biortech.2014.01.108

Awasthi, M. K., Sarsaiya, S., Wainaina, S., Rajendran, K., Kumar, S., Quan, W., Duan, Y., Awasthi, S. K., Chen, H., Pandey, A., Zhang, Z., Jain, A., Taherzadeh, M. J. (2019). A critical review of organic manure biorefinery models toward sustainable circular bioeconomy: Technological challenges, advancements, innovations, and future perspectives. Renew. Sustain. Energy Rev. 111, 115–131, DOI: 10.1016/j.rser.2019.05.017

Balan, V., da Costa Sousa, L., Chundawat, S. P. S., Vismeh, R., Jones, A. D., Dale, B. E. (2008). Mushroom spent straw: a potential substrate for an ethanol-based biorefinery. J. Ind. Microbiol. Biotechnol. 35, 293–301. DOI: 10.1007/s10295-007-0294-5

Buyukkamaci, N., Filibeli, A. (2004). Volatile fatty acid formation in an anaerobic hybrid reactor. Process Biochem. 39, 1491–1494, DOI: 10.1016/S0032-9592(03)00295-4

Corro, G., Panigua, L., Pal, U., Banuelos, F., Rosas, M. (2013). Generation of Biogas from Coffe Pulp and Cow-Dung Co-Digestion: Infrared studies of postcombustio emission. Energy Conversion and Management, 74, 471-481, DOI: 10.1016/j.enconman.2013.07.017

Dai, X., Tian, Y., Li, J., Su, X., Wang, X., Zhao, S., Liu, L., Luo, Y., Liu, D., Zheng, H., Wang, J., Dong, Z., Hu, S., Huang, L. (2015). Metatranscriptomic Analyses of Plant Cell Wall Polysaccharide Degradation by Microorganisms in the Cow Rumen. Appl. Environ. Microbiol. 81, 1375–1386, DOI: 10.1128/AEM.03682-14

Deng, Y., Huang, Z., Ruan, W., Zhao, M., Miao, H., Ren, H. (2017). Co-inoculation of cellulolytic rumen bacteria with methanogenic sludge to enhance methanogenesis of rice straw. Int. Biodeterior. Biodegrad. 117, 224–235, DOI: 10.1016/j.ibiod.2017.01.017

Garrote, G., Dominguez, H., Parajo, J.C. (2002). Autohydrolysis of corncob: study of non-isothermal operation for xylooligosaccharid production. J. Food Eng. 52, 211–218. DOI: 10.1016/S0260-8774(01)00108-X

Ghosh, P., Shah, G., Chandra, R., Sahota, S., Kumar, H., Vijay, V. K., Thakur, I. S. (2019). Assessment of methane emissions and energy recovery potential from the municipal solid waste landfills of Delhi, India. Bioresource Technology. 272, 611–615, DOI: 10.1016/j.biortech.2018.10.069

Ghosh, P., Kumar, M., Kapoor, R., Kumar, S. S., Singh, L., Vijay, V., Vijay, V. K., Kumar, V., Thakur, I. S. (2020). Enhanced biogas production from municipal solid waste via co-digestion with sewage sludge and metabolic pathway analysis. Bioresource Technolog. 296, 122275. DOI: 10.1016/j.biortech.2019.122275

Ghosh, P., Shah, G., Sahota, S., Singh, L., Vijay, V. K. (2020). Biogas production from waste: technical overview, progress, and challenges. Bioreactors, 89-104, DOI: 10.1016/B978-0-12-821264-6.00007-3

Gunter, B. (2011). Pre-treatment Technology for Biogas Production, Istanbul Bioenergy, International Symposium on Anaerobic Digestion of Solid Waste and Energy Crop, Turkey.

Henderson, G., Cox, F., Ganesh, S., Jonker, A., Young, W., Janssen, P. H. (2015). Rumen microbial community composition varies with diet and host, but a core microbiome is found across a wide geographical range. Sci. Rep. 5, 14567. DOI: 10.1038/srep14567

Isroi. (2013). Analisis Kandungan Lignoselulosa dengan Metode Chesson-datta. Balai Penelitian Bioteknologi Perkebunan Indonesia.

Jürgensen, L., Ehimen, E. A., Born, J., Holm-Nielsen, J. B. (2015). Dynamic biogas upgrading based on the Sabatier process: Thermodynamic and dynamic process simulation. Bioresource Technology. 178, 323–329, DOI: 10.1016/j.biortech.2014.10.069

Khaleghian, H., Karimi, K., Behzad, T. (2015). Ethanol production from rice straw by sodium carbonate pretreatment and Mucor hiemalis fermentation. Ind. Crops Prod. 76, 1079–1085, DOI: 10.1016/j.indcrop.2015.08.008

Lazuka, A., Auer, L., Bozonnet, S., Morgavi, D. P., O’Donohue, M., Hernandez-Raquet, G. (2015). Efficient anaerobic transformation of raw wheat straw by a robust cow rumen-derived microbial consortium. Bioresource Technology. 196, 241–249, DOI: 10.1016/j.biortech.2015.07.084

Li, C., Chen, C., Wu, X., Tsang, C.-W., Mou, J., Yan, J., Liu, Y., Lin, C. S. K. (2019). Recent advancement in lignin biorefinery: With special focus on enzymatic degradation and valorization. Bioresource Technology. 291, 121898. DOI: 10.1016/j.biortech.2019.121898

Li, F., Zhang, P., Zhang, G., Tang, X., Wang, S., Jin, S. (2017). Enhancement of corn stover hydrolysis with rumen fluid pretreatment at different solid contents: Effect, structural changes and enzymes participation. Int. Biodeterior. Biodegrad. 119, 405–412, DOI: 10.1016/j.ibiod.2016.10.038

Lopes, W. (2004). Influence of inoculum on performance of anaerobic reactors for treating municipal solid waste. Bioresource. Technology. 94, 261–266, DOI: 10.1016/j.biortech.2004.01.006

Ma, Y., Shen, Y., Liu, Y. (2020). Food Waste to Biofertilizer: A Potential Game Changer of Global Circular Agricultural Economy. J. Agric. Food Chem. 68, 5021–5023, DOI: 10.1021/acs.jafc.0c02210

Ma, Y., Yin, Y., Liu, Y. (2017). Corrigendum to “New insights into co-digestion of activated sludge and food waste: Biogas versus biofertilizer”. Bioresource Technology. 241, 448–453, DOI: 10.1016/j.biortech.2017.07.152

Ma, Y., Yin, Y., Liu, Y. (2017). A holistic approach for food waste management towards zero-solid disposal and energy/resource recovery. Bioresoure Technology. 228, 56–61, DOI: 10.1016/j.biortech.2016.12.090

Sonakya, V., Raizada, N., Dalhoff, R., Wilderer, P. A. (2003). Elucidation mechanism of organic acids production from organic matter (grass) using digested and partially digested cattle feed. Water Sci. Technology. 48, 255–259, DOI: 10.2166/wst.2003.0476

Sun, Q., Li, H., Yan, J., Liu, L., Yu, Z., Yu, X. (2015). Selection of appropriate biogas upgrading technology-a review of biogas cleaning, upgrading and utilisation. Renew. Sustain. Energy Rev, 51, 521–532, DOI: 10.1016/j.rser.2015.06.029

Xing, B.-S., Han, Y., Cao, S., Wen, J., Zhang, K., Yuan, H., Wang, X. C. (2020). Cosubstrate strategy for enhancing lignocellulose degradation during rumen fermentation in vitro: Characteristics and microorganism composition. Chemosphere. 250, 126104, DOI: 10.1016/j.chemosphere.2020.126104

Yadvika, Santosh, Sreekrishnan, T. R., Kohli, S., Rana, V. (2004). Enhancement of biogas production from solid substrates using different techniques-a review. Bioresource Technology. 95, 1–10, DOI: 10.1016/j.biortech.2004.02.010

Zhang, C., Su, H., Baeyens, J., Tan, T. (2014). Reviewing the anaerobic digestion of food waste for biogas production. Renew. Sustain. Energy Rev. 38, 383–392. DOI: 10.1016/j.rser.2014.05.038

Zhong, C., Lau, M. W., Balan, V., Dale, B. E., Yuan, Y.-J. (2009). Optimization of enzymatic hydrolysis and ethanol fermentation from AFEX-treated rice straw. Appl. Microbiol. Biotechnol. 84, 667–676, DOI: 10.1007/s00253-009-2001-0

Article Metrics

Abstract has been read : 826 timesDOWNLOAD PDF file viewed/downloaded: 0 times

DOI: http://doi.org/10.25273/cheesa.v4i1.7406.1-10

Refbacks

- There are currently no refbacks.

This work is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License.