Optimization of Ulva sp. Decomposition using H2SO4 with Microwave-Assisted Hydrolysis Method as Feedstock of Bioethanol

Abstract

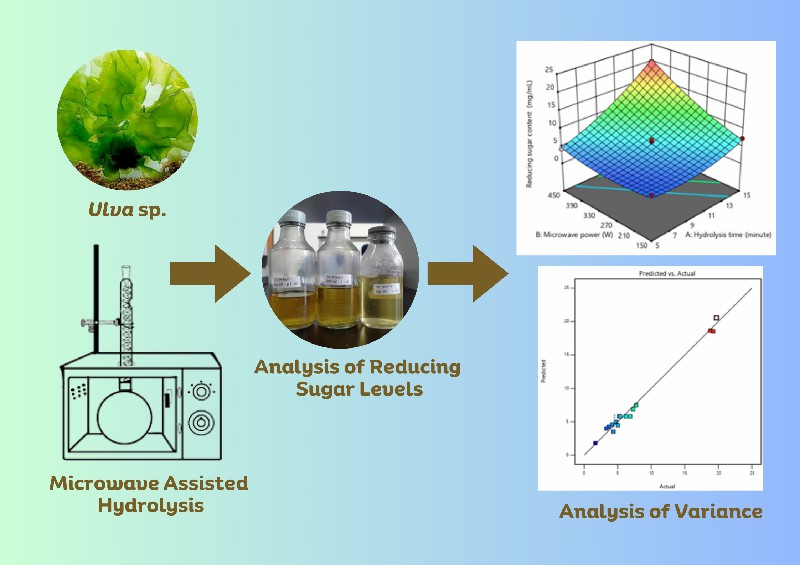

Bioethanol is a renewable energy used to reduce dependence on fossil fuels, which have negative impacts on the environment. Furthermore, Ulva sp. contains high levels of carbohydrates, making it potentially suitable as a raw material for bioethanol production. Therefore, this study aims to determine the optimal decomposition process using the microwave-assisted hydrolysis method with an acid solvent (H2SO4), by examining the effects of acid concentration, hydrolysis time, and microwave power. Optimization was carried out using several parameters such as hydrolysis time, microwave power, and the ratio of raw materials to solvents. The ANOVA test results showed that the hydrolysis variable parameter had a significant effect on the reducing sugar content obtained, evidenced by the R2 value of 0.9892. The highest reducing sugar content of 19.71 mg/mL was produced under the operating conditions of 15 min hydrolysis time, 450 W microwave power, and 0.065 g/mL ratio of raw material to solvents.

Keywords

Full Text:

DOWNLOAD PDFReferences

Aiman, S. (2014). Perkembangan Teknologi Dan Tantangan Dalam Riset Bioetanol Di Indonesia. Jurnal Kimia Terapan Indonesia. DOI: 10.14203/jkti.v16i2.16

Aniriani, G. W., Apriliani, N. F., & Sulistiono, E. (2018). Hydrolysis of Polycoxarida Xylane Straw Using Strong Acid Acid Solution for Basic Materials of Bioetanol Production. Jurnal Ilmiah Sains, 18(2), 113–117.

Ardinata, R. A. & Manguntungi, B. (2020). Inovasi Pemanfaatan Ekstrak Alga Hijau Ulva sp dari Pantai Luk,Sumbawa Sebagai Kandidat Antibakteri Terhadap Salmonella thypi dan Staphylococcus aureus. Jurnal TAMBORA, 4(3), 1–6. DOI: 10.36761/jt.v4i3.785

Azhar, M., & Satriawan, D. A. (2018). Implementasi Kebijakan Energi Baru dan Energi Terbarukan Dalam Rangka Ketahanan Energi Nasional. Administrative Law and Governance Journal, 1(4), 398–412. DOI: 10.14710/alj.v1i4.398-412

Darojati, H. A. (2017). Prospek Pengembangan Teknologi Radiasi Sebagai Perlakuan Pendahuluan Biomassa Lignoselulosa. Jurnal Forum Nuklir, 11(2), 71. DOI: 10.17146/jfn.2017.11.2.5313

Dave, N., Selvaraj, R., Varadavenkatesan, T., & Vinayagam, R. (2019). A critical review on production of bioethanol from macroalgal biomass. Algal Research, 42(June), 101606. DOI: 10.1016/j.algal.2019.101606

Dave, N., Varadavenkatesan, T., Selvaraj, R., & Vinayagam, R. (2021). Modelling Of Fermentative Bioethanol Production From Indigenous Ulva Prolifera Biomass By Saccharomyces Cerevisiae Nfcci1248 Using An Integrated Ann-Ga Approach. Science of the Total Environment, 791, 148429. DOI: 10.1016/j.scitotenv.2021.148429

Dominguez, H., & Loret, E. P. (2019). Ulva lactuca, A Source of Troubles and Potential Riches. Marine Drugs, 17(6). DOI: 10.3390/md17060357

ElHarchi, M., Kachkach, F. Z., & ElMtili, N. (2018). Optimization Of Thermal Acid Hydrolysis For Bioethanol Production From Ulva Rigida With Yeast Pachysolen Tannophilus. South African Journal of Botany, 115, 161–169. DOI: 10.1016/j.sajb.2018.01.021

Galung, F. S. (2021). Analisis Kandungan Karbohidrat (Glukosa) Pada Salak Golla – Golla. Journal of Agritech Science, 5(1), 10–14

Greiserman, S., Epstein, M., Chemodanov, A., Steinbruch, E., Prabhu, M., Guttman, L., …Golberg, A. (2019). Co-production of Monosaccharides and Hydrochar from Green Macroalgae Ulva (Chlorophyta) sp. with Subcritical Hydrolysis and Carbonization. Bioenergy Research, 12(4), 1090–1103. DOI: 10.1007/s12155-019-10034-5

Gusnedi, R. (2013). Analisis Nilai Absorbansi dalam Penentuan Kadar Flavonoid untuk Berbagai Jenis Daun Tanaman Obat. Pillar of Physics, 2, 76–83.

Habibah, F., Budi, S., Kusuma, W., & Wijayati, N. (2016). Produksi Substrat Fermentasi Bioetanol dari Alga Merah Gracilaria verrucosa. Indonesian Journal of Chemical Science, 5(1), 36–41. DOI: LINK

Hebbale, D., Bhargavi, R., & Ramachandra, T.V. (2019). Saccharification of macroalgal polysaccharides through prioritized cellulase producing bacteria. Heliyon, 5(3), e01372. DOI: 10.1016/j.heliyon.2019.e01372

Hidayat, I. R., Zuhrotun, A., & Sopyan, I. (2020). Design-Expert Software sebagai Alat Optimasi Formulasi Sediaan Farmasi. Majalah Farmasetika, 6(1), 99–120. DOI: 10.24198/mfarmasetika.v6i1.27842

Jaya, D., Setiyaningtyas, R., & Prasetyo, S. (2018). Pembuatan Bioetanol Dari Alga Hijau Spirogyra Sp Bioethanol Production From Green Algae Spirogyra sp. Eksergi, 15(1), 16–19.

Jiang, R., Linzon, Y., Vitkin, E., Yakhini, Z., Chudnovsky, A., & Golberg, A. (2016). Thermochemical hydrolysis of macroalgae Ulva for biorefinery: Taguchi robust design method. Scientific Reports, 6(June), 1–14. DOI: 10.1038/srep27761

Kavitha, S., Rajesh Banu, J., Kumar, G., Kaliappan, S., & Yeom, I. T. (2018). Profitable ultrasonic assisted microwave disintegration of sludge biomass: Modelling of biomethanation and energy parameter analysis. Bioresource Technology, 254(December 2017), 203–213. DOI: 10.1016/j.biortech.2018.01.072

Khan, H., Khan, I., & Binh, T. T. (2020). The heterogeneity of renewable energy consumption, carbon emission and financial development in the globe: A panel quantile regression approach. Energy Reports, 6, 859–867. DOI: 10.1016/j.egyr.2020.04.002

Kim, D. H., Lee, S. B., & Jeong, G. T. (2014). Production of reducing sugar from Enteromorpha intestinalis by hydrothermal and enzymatic hydrolysis. Bioresource Technology, 161, 348–353. DOI: 10.1016/j.biortech.2014.03.078

Kolo, S. M. D., & Edi, E. (2018). Hidrolisis Ampas Biji Sorgum dengan Microwave untuk Produksi Gula Pereduksi sebagai Bahan Baku Bioetanol. Jurnal Saintek Lahan Kering, 1(2), 22–23. DOI: 10.32938/slk.v1i2.596

Kolo, S. M. D., Obenu, N. M., dan Tuas, M. Y. C. (2022). Pengaruh Pretreatment Makroalga Ulva Reticula Menggunakan Microwave Irradiation Untuk Produksi Bioetanol, 16(2), 212–219. DOI: 10.24843/JCHEM.2022.v16.i02.p12

Kolo, S. M. D., Presson, J., & Amfotis, P. (2021). Produksi Bioetanol Sebagai Energi Terbarukan Dari Rumput Laut Ulva Reticulata Asal Pulau Timor. ALCHEMY Jurnal Penelitian Kimia, 17(2), 159. DOI: 10.20961/alchemy.17.2.45476.159-167

Kolo, S. M. D., Wahyuningrum, D., & Hertadi, R. (2020). The Effects of Microwave-Assisted Pretreatment and Cofermentation on Bioethanol Production from Elephant Grass. International Journal of Microbiology, 2020. DOI: 10.1155/2020/6562730

Kostas, E. T., Beneroso, D., & Robinson, J. P. (2017). The application of microwave heating in bioenergy: A review on the microwave pre-treatment and upgrading technologies for biomass. Renewable and Sustainable Energy Reviews, 77(November 2016), 12–27. DOI: 10.1016/j.rser.2017.03.135

Kostas, E. T., White, D. A., & Cook, D. J. (2020). Bioethanol Production from UK Seaweeds: Investigating Variable Pre-treatment and Enzyme Hydrolysis Parameters. Bioenergy Research, 13(1), 271–285. DOI: 10.1007/s12155-019-10054-1

Kumar, M. D., Kaliappan, S., Gopikumar, S., Zhen, G., & Banu, J. R. (2019). Synergetic pretreatment of algal biomass through H2O2 induced microwave in acidic condition for biohydrogen production. Fuel, 253(March), 833–839. DOI: 10.1016/j.fuel.2019.05.066

Kusmiyati, K., Heratri, A., Kubikazari, S., Hidayat, A., & Hadiyanto, H. (2020). Hydrolysis of microalgae spirulina platensis, chlorella sp., and macroalgae ulva lactuca for bioethanol production. International Energy Journal, 20(4), 611–620.

Lastriyanto, A. & Aulia, A. I. (2021). Analisa Kualitas Madu Singkong (Gula Pereduksi, Kadar Air, dan Total Padatan Terlarut) Pasca Proses Pengolahan dengan Vacuum Cooling. Jurnal Ilmu Produksi dan Teknologi Hasil Peternakan, 9(2), 110–114. DOI: 10.29244/jipthp.9.2.110-114

Li, Y., Cui, J., Zhang, G., Liu, Z., Guan, H., Hwang, H., …Wang, P. (2016). Optimization Study On The Hydrogen Peroxide Pretreatment And Production Of Bioethanol From Seaweed Ulva Prolifera Biomass. Bioresource Technology, 214, 144–149. DOI: 10.1016/j.biortech.2016.04.090

Margareta, W., Nagarajan, D., Chang, J. S., & Lee, D. J. (2020). Dark fermentative hydrogen production using macroalgae (Ulva sp.) as the renewable feedstock. Applied Energy, 262(December 2019), 114574. DOI: 10.1016/j.apenergy.2020.114574

Ngamput, H. M. A., & Herrani, R. (2019). The Effect Of Differentiation Of Hydrolysis Time Towards Ethanol Levels Produced Through Ulva Lactuca Fermentation. Journal of Physics: Conference Series, 1241(1). DOI: 10.1088/1742-6596/1241/1/012010

Nugroho, D., & Rianto, A. (2022). Strategi Indonesia Dalam Mengurangi Emisi Karbon Dioksida (CO2) Di Masa New Normal. Prosiding Ilmu Pemerintahan, 1(1), 228–242.

Nur, O. (2014). Chlorophyta. Implementation Science, 39(1), 1–24.

Offei, F., Mensah, M., & Thygesen, A. (2018). Produksi Bioetanol Rumput Laut: Seleksi Proses Ulasan tentang Hidrolisis dan Fermentasi. DOI: 10.3390/fermentasi4040099

Özçimen, D. & İnan, B. An overview of bioethanol production from algae. (2015). Biofuels-Status and Perspective, 141–162.

Palupi, B., Fachri, B. A., Rahmawati, I., Rizkiana, M. F., & Amini, H. W. (2020). Pretreatment of tobacco stems as bioethanol raw material: The effect of temperature and time using chemical method. AIP Conference Proceedings, 2278(October). DOI: 10.1063/5.0014558

Paminto, A. K. (2020). Analisis Dan Proyeksi Kebutuhan Energi Sektor Transportasi Di Indonesia. Jurnal Energi dan Lingkungan (Enerlink), 16(2), 51–54. DOI: 10.29122/jel.v16i2.4801

Pertamina. (2020). Pertamina Energy Outlook 2020, 1–128.

Poespowati, T., & Mahmudi, A. (2018). Optimization Of Acid Hydrolysis Process On Macroalga Ulva Lactuca For Reducing Sugar Production As Feedstock Of Bioethanol. International Journal of Renewable Energy Research, 8(1), 466–475. DOI: 10.20508/ijrer.v8i1.7069.g7322

Pribadi, A. (2020). Forum Kehumasan Dewan Energi Nasional: Menuju Bauran Energi Nasional Tahun 2025. LINK

Putri, L. E. (2017). Penentuan Konsentrasi Senyawa Berwarna KMnO4 Dengan Metoda Spektroskopi UV Visible. Natural Science Journal, 3(1), 391–398.

Raheem, A., Prinsen, P., Vuppaladadiyam, A. K., Zhao, M., & Luque, R. (2018). A review on sustainable microalgae based biofuel and bioenergy production: Recent developments. Journal of Cleaner Production, 181, 42–59. DOI: 10.1016/j.jclepro.2018.01.125

Ramachandra, T.V., & Hebbale, D. (2020). Bioethanol from macroalgae: Prospects and challenges. Renewable and Sustainable Energy Reviews, 117(September 2019), 109479. DOI: 10.1016/j.rser.2019.109479

Ramadhani, R. A., Riyadi, D. H. S., Triwibowo, B., & Kusumaningtyas, R. D. (2017). Review Pemanfaatan Design Expert untuk Optimasi Komposisi Campuran Minyak Nabati sebagai Bahan Baku Sintesis Biodiesel. Jurnal Teknik Kimia dan Lingkungan, 1(1), 11. DOI: 10.33795/jtkl.v1i1.5

Ramdan, M. R., & Nuraeni, E. (2021). Identifikasi Morfologi Ulva intestinalis dan Acanthophora spicifera di Kawasan Pantai Tanjung Layar, Sawarna, Bayah, Kabupaten Lebak, Banten. Tropical Bioscience: Journal of Biological Science, 1(1), 1–10.

Rilek, N. M., Hidayat, N. & Sugiarto, Y. (2017). Hidrolisis Lignoselulosa Hasil Pretreatment Pelepah Sawit (Elaeis guineensis Jacq) menggunakan H2SO4 pada Produksi Bioetanol. Industria: Jurnal Teknologi dan Manajemen Agroindustri, 6(2), 76–82. DOI: 10.21776/ub.industria.2017.006.02.3

Rokhati, N. (2017). Pengaruh Pretreatment Iradiasi Microwave Pada Hidrolisis Kitosan Dengan Enzim Cellulase. Jurnal Aplikasi Teknologi Pangan, 6(1), 7–11. DOI: 10.17728/jatp.212

Roni, K. A. (2015). Pembuatan Bioethanol dari Tanah Gambut dengan Proses Hidrolisis Asam Kuat. Berkala Teknik, 5(1), 801–813.

Sabathani, A., Widjanarko, S. B., & Yuwono, S. S. (2018). Optimasi Durasi Dan Rasio Bahan Per Pelarut Ekstrak Daun Pepaya Untuk Uji Aktivitas Antibakteri. Jurnal Teknologi Pertanian, 19(3), 193–206. DOI: 10.21776/ub.jtp.2018.019.03.6

Sandra, O. A., Nugroho, W. A., & Yulianingsih, R. (2015). Studi Pengaruh Pretreatment Hidrotermal Terhadap Fermentasi Simultan Pada Rumput Laut (Ulva Lactuca) Menjadi Bioetanol. Jurnal Bioproses Komoditas Tropis, 3(1), 68–72.

Santoso, B., Nabilla, A., Rahayu, S., Bondan, A.T., & Selpiana, S. (2020). Ekstraksi minyak biji ketapang menggunakan microwave pretreatment: pengaruh massa biji ketapang dan waktu radiasi. Jurnal Teknik Kimia, 26(2), 80–87. DOI: 10.36706/jtk.v26i2.543

Trivedi, N., Gupta, V., Reddy, C. R. K., & Jha, B. (2013). Enzymatic Hydrolysis And Production Of Bioethanol From Common Macrophytic Green Alga Ulva Fasciata Delile. Bioresource Technology, 150, 106–112. DOI: 10.1016/j.biortech.2013.09.103

Tsubaki, S., Oono, K., Hiraoka, M., Ueda, T., Onda, A., Yanagisawa, K., & Azuma, J. I. (2014). Hydrolysis of green-tide forming Ulva spp. by microwave irradiation with polyoxometalate clusters. Green Chemistry, 16(4), 2227–2233. DOI: 10.1039/c3gc42027b

Winahyu, D. A., Retnaningsih, A., & Aprilia, M. (2019). Penetapan Kadar Flavonoid Pada Kulit Batang Kayu Baru Dengan Metode Spektrofotometri UV-VIS. Jurnal Analisis Farmasi, 4(1), 29–36.

Wu, Z. Z., Li, D. Y., & Cheng, Y. S. (2018). Application of ensilage as a green approach for simultaneous preservation and pretreatment of macroalgae Ulva lactuca for fermentable sugar production. Clean Technologies and Environmental Policy, 20(9), 2057–2065. DOI: 10.1007/s10098-018-1574-7

Yoo, G., Park, M. S., & Yang, J. W. (2015). Chemical Pretreatment of Algal Biomass. Pretreatment of Biomass: Processes and Technologies. Elsevier B.V. DOI: 10.1016/B978-0-12-800080-9.00012-8

Yu, K. L., Chen, W. H., Sheen, H. K., Chang, J. S., Lin, C. S., Ong, H. C., …Ling, T. C. (2020). Production of microalgal biochar and reducing sugar using wet torrefaction with microwave-assisted heating and acid hydrolysis pretreatment. Renewable Energy, 156, 349–360. DOI: 10.1016/j.renene.2020.04.064

Zelvi, M., Suryani, A., & Setyaningsih, D. (2017). Hidrolisis Eucheuma Cottonii Dengan Enzim K-Karagenase Dalam Menghasilkan Gula Reduksi Untuk Produksi Bioetanol. Jurnal Teknologi Industri Pertanian, 27(1), 33–42. DOI: 10.24961/j.tek.ind.pert.2017.27.1.33

Article Metrics

Abstract has been read : 301 timesDOWNLOAD PDF file viewed/downloaded: 0 times

DOI: http://doi.org/10.25273/cheesa.v6i1.14682.13-25

Refbacks

- There are currently no refbacks.

This work is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License.